Collateral for Umpqua Bank Brand Identity Event

With the merge of Columbia Bank and Umpqua Bank, there was a brand redesign. An unveiling of the new brand would happen at an event with the marketing team.

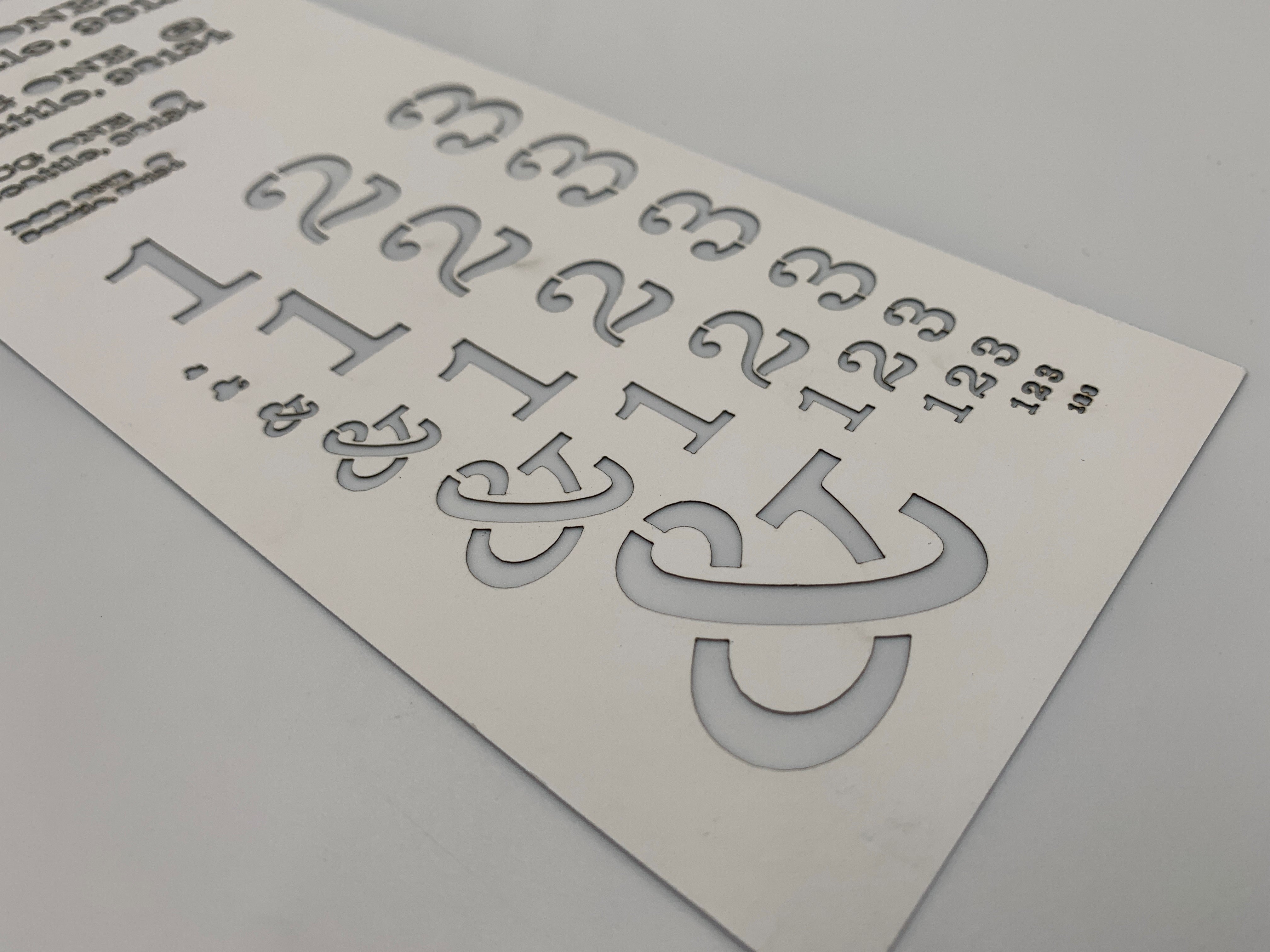

The accordion folded brochures of the new identity would normally be die cut, however the detailed features were best suited for laser cutting. DCG One reached out to Kurblink to see if laser cutting could eliminate chads and other burrs that die cutting would leave behind.

After running samples (left), DCG One decided to move ahead. Kurblink readied equipment to do a quick turn on over 800 units.

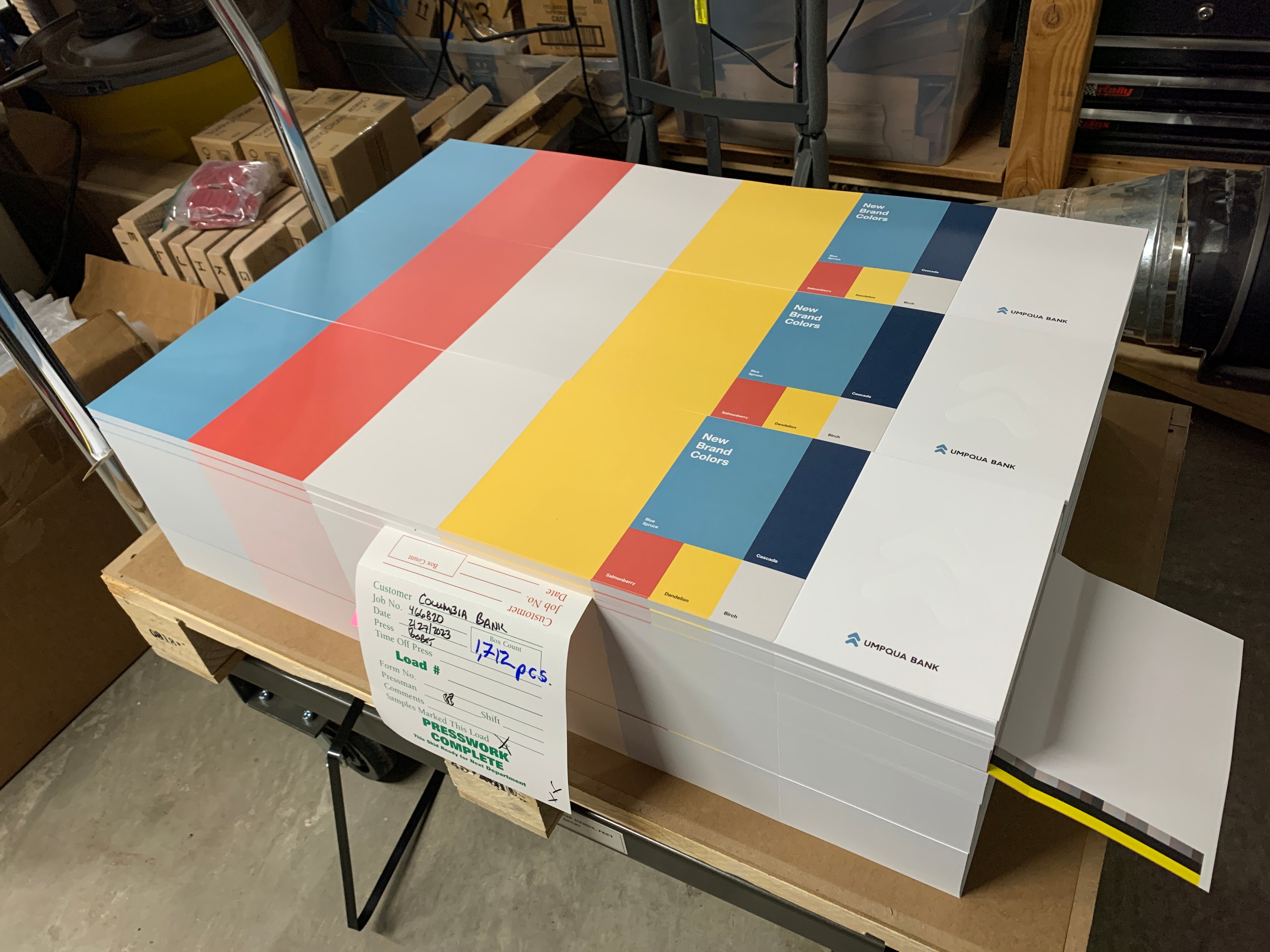

Material arrives

Material arrives at Kurblink, and a deadline has been set. Overrun is normal, and in this case it was necessary. While cutting, units with blemishes were able to be set aside and unprocessed. This ensured the required quantity could be fulfilled using perfectly printed sheets. There were still a bunch of good leftovers.

Reliable execution

A project like this requires a solid setup. Not only is speed and efficiency required, but repeatable quality results. Kurblink actually modified it's CO2 laser equipment to accept fixturing for this and future jobs. This proved to be critical and a worthwhile investment of time. The images below will take you through the process of completing this project. Spoiler alert >>> we delivered ahead of schedule.

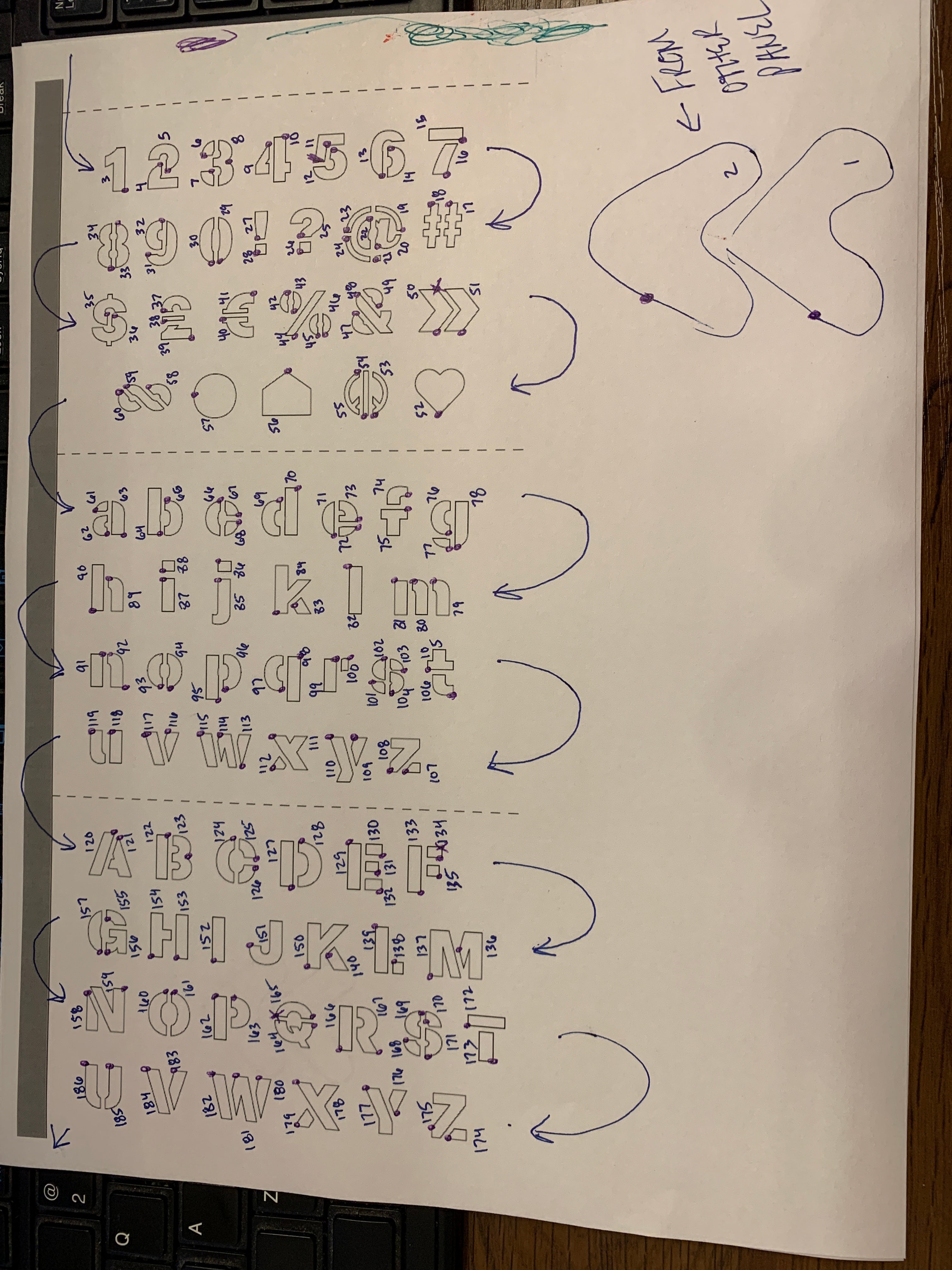

Programmed

Our programming software will auto generate a program, but that's not optimal when running a large quantity of units; especially one this complex. Not only is the reduction of traverse time important, but also optimizing the tool path so the laser head doesn't collide with "tilt-ups." Hand notes as seen here keep things organized throughout the process.

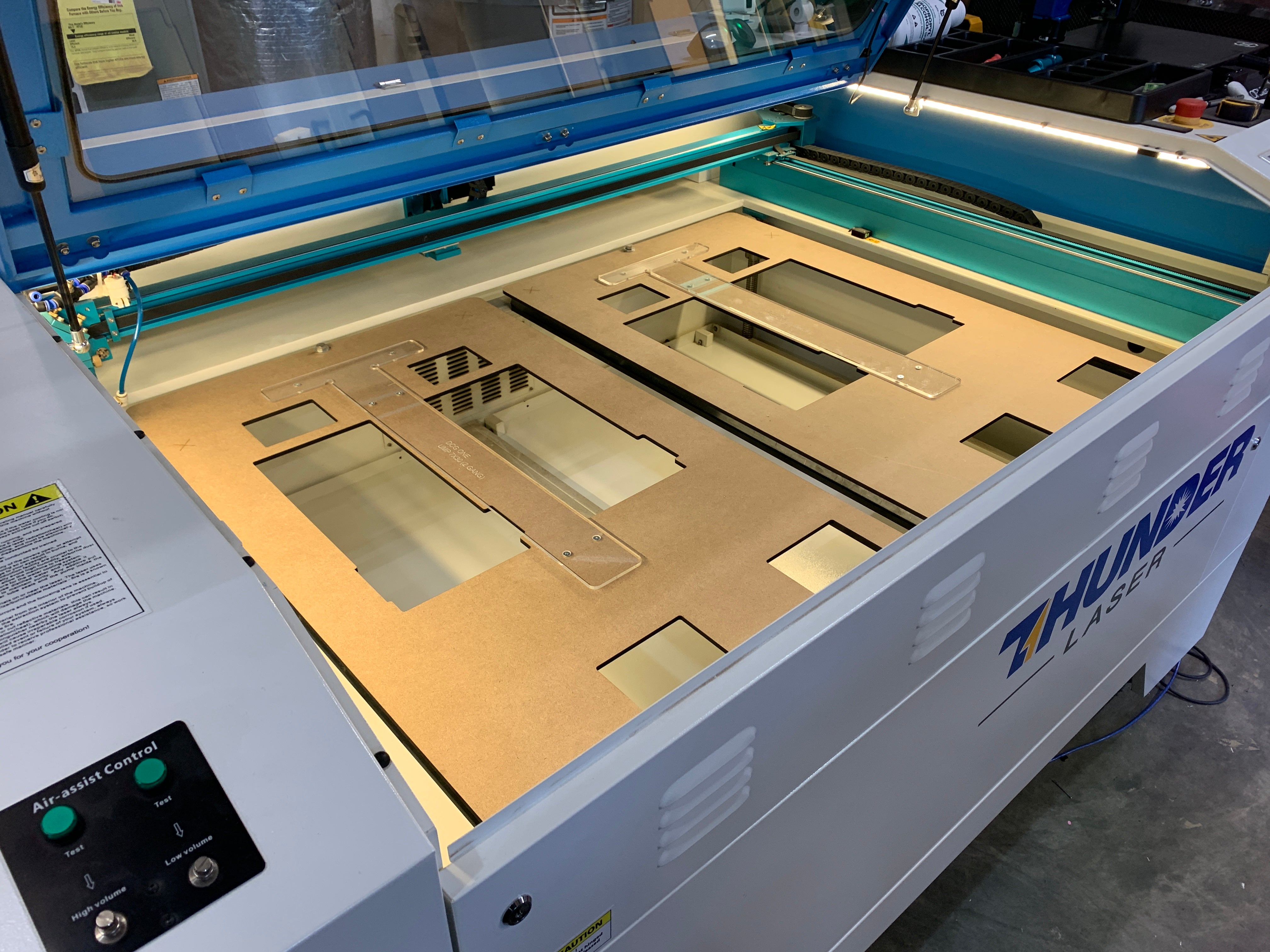

Fixtures designed

Special designed fixtures were made for this project. The machine itself was modified to accept the fixtures. Future projects can utilize the same format we chose. This will speed up setup times moving forward.

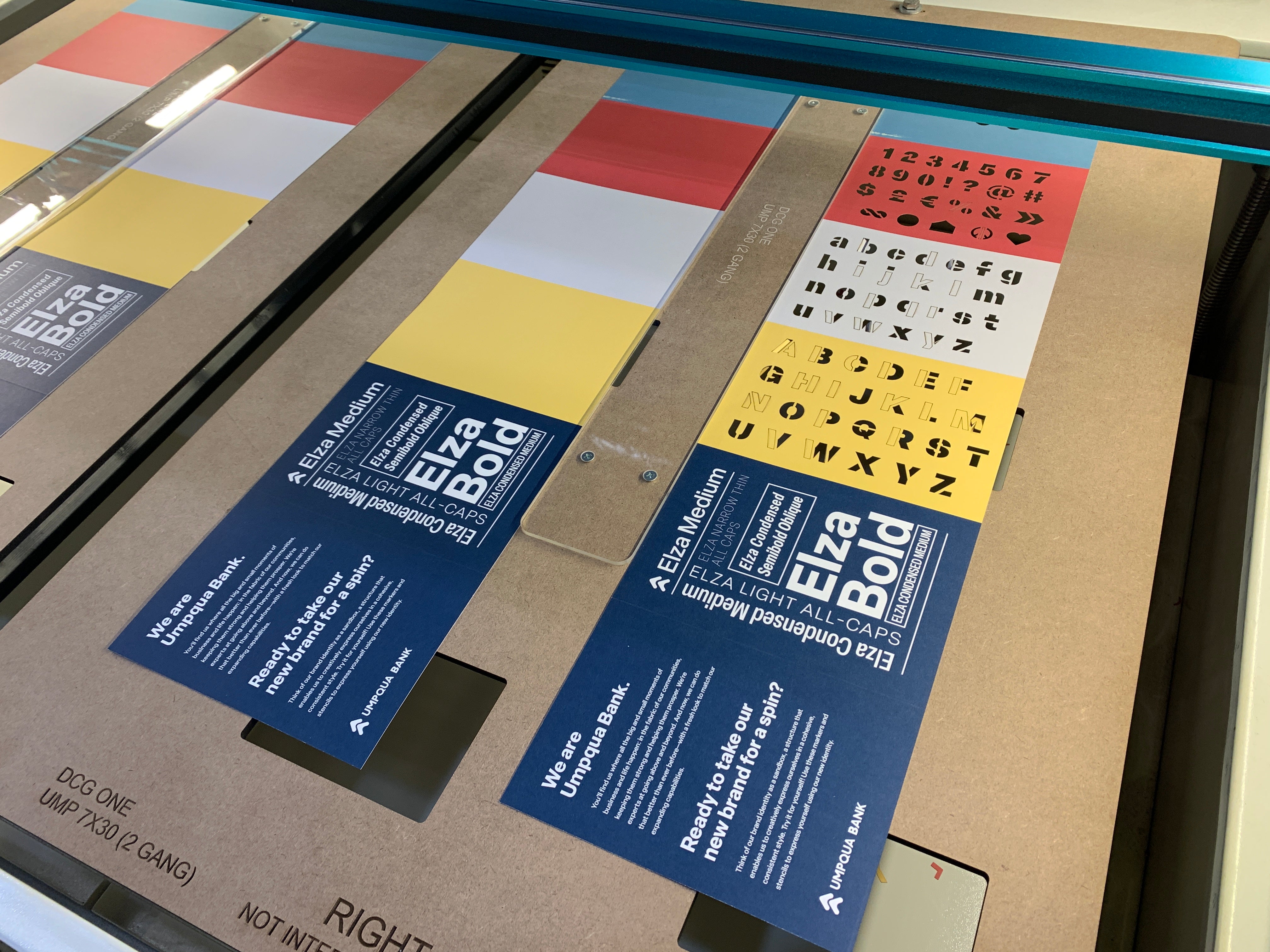

Test run

While everything can look good on paper, reality can look different. Our test proved the card stock sheets could be reliably indexed squarely for cutting and that waste elements could fall away as planned. Clearance windows for handling ensured the sheets would sustain as little stress as possible and edges would stay crisp.

Production

Once production had begun, Kurblink welcomed a few DCG One team members in for an inspection of the parts and process. It was not only a great way to meet the team, but crucial for ensuring the results were matching expectation.

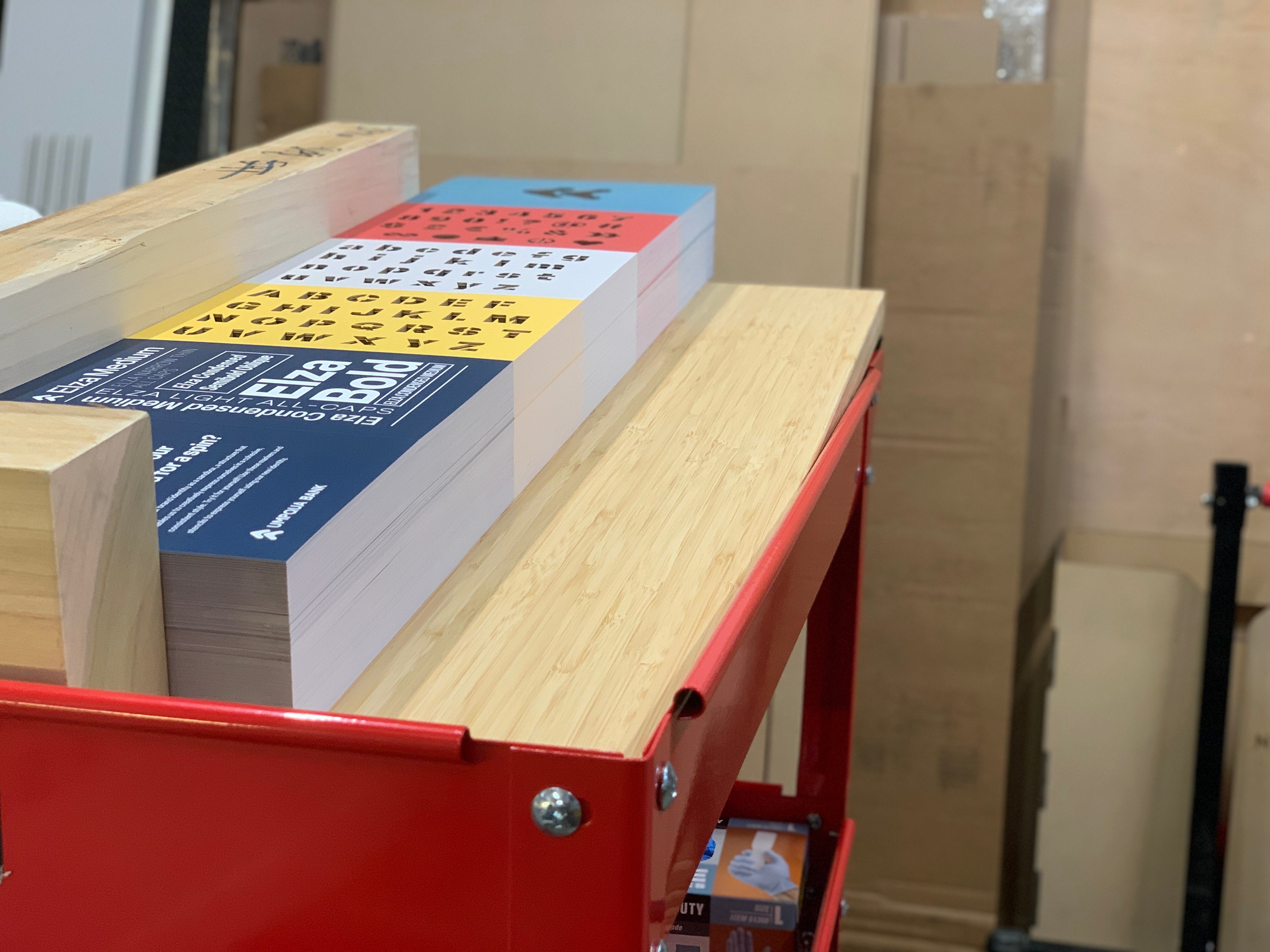

Final units cut

This was a long running job with no downtime between cycles. The program was set to run continuously with loading and emptying happening while the machine cut at opposite ends of the bed. Enough to make you go crazy. I love it.

Drops collected

There were somewhere in the neighborhood of 153,450 drops from all the features cut. Since this was a confidential job and all materials were to be returned to DCG One, of course these were scooped up and boxed attention to the Account Executive who awarded me the work. I hope she took it in good humor. All I know is I wasn't called over to clean up any mess from the unboxing.